Piston Pocketing

Piston pocketing refers to the process of machining small recesses or “pockets” into the tops of pistons. This is typically done to provide additional clearance for the valves, especially in high-performance engines where larger camshafts with higher lift are used. The pockets prevent the valves from making contact with the pistons during the engine’s operation, which can cause serious damage.

Purpose: To ensure adequate clearance between the pistons and valves.

When Needed: Often required when using high-lift camshafts or larger valves.

Process: Machining small recesses into the piston tops.

Benefits: Prevents valve-to-piston contact, allowing for more aggressive cam profiles and improved engine performance.

DYNO TUNING: HYPERDYNO

The HYPERDYNO measures the dynamic wheel power and the power loss in the transmission, and displays the effective engine power (brake horsepower) directly as the sum of the two.

A test-roller set with a defined inertia effect (inertia flywheel) is driven and accelerated by the vehicle's driving wheels.

The power at the wheels can be determined from the acceleration of the Dynamometer mass with the engine running at wide-open throttle (WOT).

Upon reaching the measurement speed, the engine is disconnected from the remaining drive elements by declutching. The energy stored in the test-roller set now drives all the transmission elements with which the test rollers are in contact.

The power loss is determined from the deceleration resulting from the rolling resistance, and from the transmission and bearing resistances.

Using the wheel power and the power loss, an electronic evaluation unit calculates the engine power at the clutch.

The evaluation circuitry measures the wheel power during acceleration and the power loss during deceleration.

In accordance with DIN 70020, the engine power is displayed at rated engine speed, referred to standard conditions of + 20C and an atmospheric pressure of 750 mm Hg (=1013 mbar), and with a permissible tolerance of + 5 %.

Non-standard atmospheric pressures and intake-air temperatures affect engine power, and must be taken into account during evaluation.

The test data required, "Engine power" and "Rated speed" are to be taken from the vehicle documents.

CUSTOM MANIFOLD (INTAKE AND TURBO) DESIGN

Rowland Manifolds does custom design sandcasting. If you need a manifold that is not in our extensive range of models, please contact us to discuss custom design. With over 24 years of experience, that custom design is an email away. Remember: we courier across South Africa and internationally.

All Rowland Manifolds are subject to our manufacturing guarantee, custom and generic.

REGULAR SERVICE, MAINTENANCE AND REPAIRS OF ALL VEHICLES AND TRUCKS TO FACTORY STANDARDS

Via our sister companies, Motordrive and RSM Motor Centre we are able to offer all clients of Rowland Manifolds a full suite of vehicle/truck repair and maintenance services. Motordrive and RSM Motor Centre are RMI members in good standing. This allows for both workshops to cover all vehicles under warranty or extended warranties. To make it easier for clients, all of the admin work is completed for them. No hassles, no waiting.

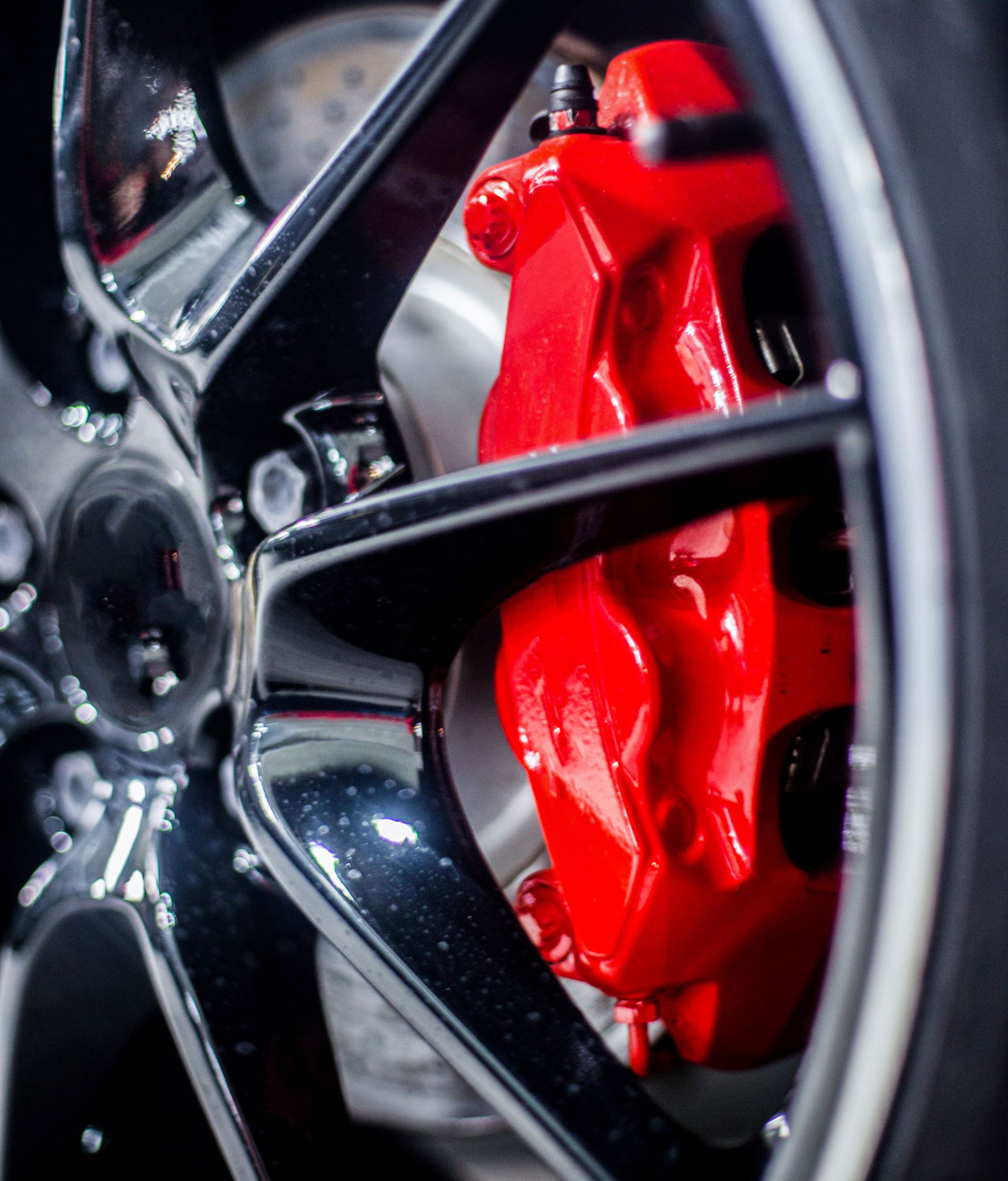

From Aircon regassing to major and minor services, from suspension repair to clutches and brakes we are here for you. Motordrive is situated directly next to Rowland Manifolds and major/minor work or conversions can be carried out.

info@motordrive.coza or info@rsmmotorcentre.co.za